- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

English

English English

English| Availability: | |

|---|---|

| Quantity: | |

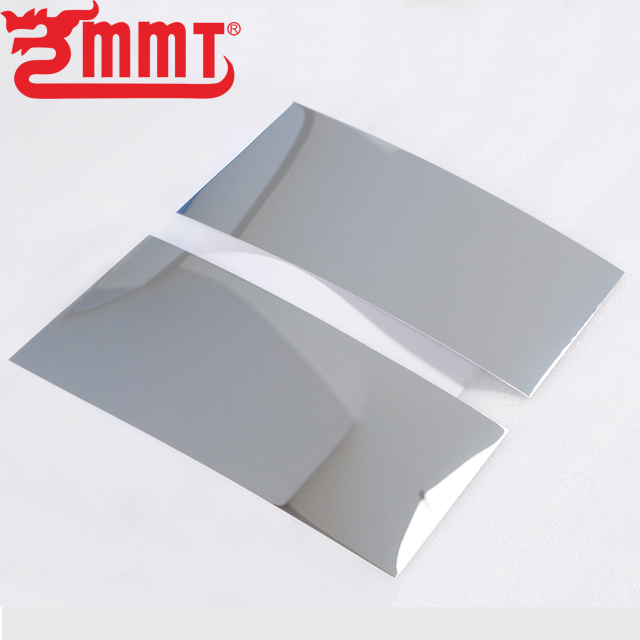

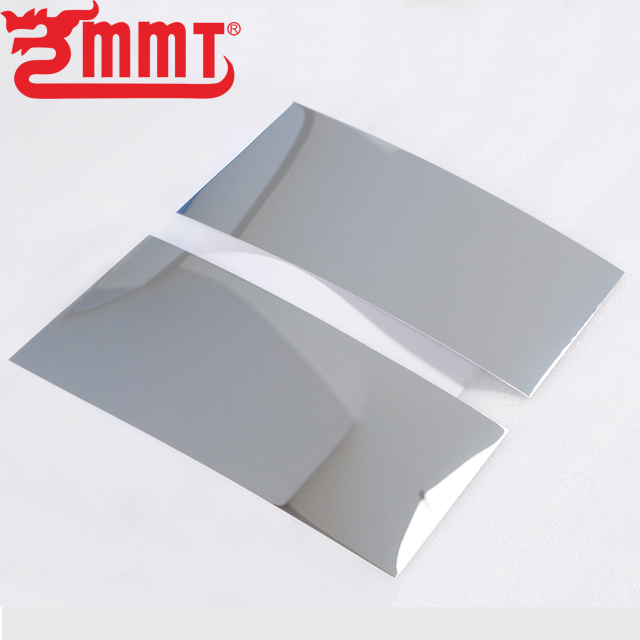

SMMT high performance Al mirror product V95 is specially designed to attain high specular reflectance and "Indoor Louver-type Light Collecting System" application.

A typical application of this material is the "Indoor Louver-Type Light Collecting System". In order to introduce the outdoor daylight into the indoor no light area or light blind areas, directly use high performance mirror material for a solar collector as a critical part of Indoor Louver-Type Light Collecting System is a most effective, energy-saving and also environmentally-friendly way to solve this problem. In this way, we are confident that our high performance mirror materials can play a key role in People's Daily Lives and make a great contribution to people's quality of life.

Products&Application

Product Specification

Product Name | High Performance Mirror | “V95” | |

Substrate Specification | Material | Aluminium Strip | |

Width [mm] | 1000 … 1250 | ||

Standard Thickness [mm] | 0.3 … 1.0 | ||

Standard Alloy | Depend on Application 1000 series, 5000 series etc. | ||

Temper | H16、H18、H19、H24 etc. | ||

Surface | Pure Al+ Pre-coating | ||

Pre-coat Thickness [μm] | ≥ 4μm | ||

Mechanical Property | Tensile Strength [N/mm²] | 300 ~ 320 | |

Yield Strength [N/mm²] | 270 ~ 300 | ||

Tension Uniformity across strip [%] | ± 2.5 | ||

Tension Uniformity along strip [%] | ± 5.0 | ||

Elongation [%] | ~ 5% | ||

Bending Radius for forming | ≥ 1.5 x strip thickness | ||

Physical Property | Density [g/cm³] | 2.7 | |

Optical Property | Total reflectance (Y / D65 / 2°) [%] | 95±2 | |

Diffuse reflectance (Y / D65 / 2°) [%] | < 1.0 | ||

Specular Reflectance (60° longitudinal) [%] | ≥ 91 | ||

Specular Reflectance (60° transversal) [%] | ≥ 91 | ||

Colour (CIELAB D65 10°) | L*: 98 ± 1 a*: 2 … 2 b*: -1 … 1 | ||

Durability Tests

| Test Item | Approval | |

NSS Salt water spray test (as coated / 72hours / ΔY% < 1%) | ΔY% < 1.5% | ||

Cross hatch adhesion test (no test fields delaminating) | 0 delamination of 100 fields | ||

Oven Test (180°C / 2h / ΔY% < 1%) | ΔY% < 0.5% | ||

Climate Chamber (40°C - 95% r.H. / 168h / ΔY% < 1.0%) | ΔY% ≤ 1.0% | ||

Climate Chamber (85°C - 85% r.H. / 24h / ΔY% < 1.0%) | ΔY% ≤ 1.0% | ||

UV test (continuous test for 2weeks / ΔY% < 1.0%) | ΔY% ≤ 1.0% | ||

Form Tolerances | Thickness Tolerances for coils and sheets [mm] | 8% of gauge | |

Width Tolerances coil [mm] | +2.00/-0.00 | ||

Width Tolerances Slit coil [mm] | +0.06/-0.00 | ||

Longitudinal Curvature coil [mm] | ≤ 1 per 1000mm length | ||

Sheet Sizes [mm] | < 1250 (width) < 4000 (length) | ||

Sheet Size tolerances [mm] | +0.50/-0.00 (< 500mm) +1.50/-0.00 (500 - 2000mm) +2.50/-0.00 (2000 - 4000mm) | ||

SMMT high performance Al mirror product V95 is specially designed to attain high specular reflectance and "Indoor Louver-type Light Collecting System" application.

A typical application of this material is the "Indoor Louver-Type Light Collecting System". In order to introduce the outdoor daylight into the indoor no light area or light blind areas, directly use high performance mirror material for a solar collector as a critical part of Indoor Louver-Type Light Collecting System is a most effective, energy-saving and also environmentally-friendly way to solve this problem. In this way, we are confident that our high performance mirror materials can play a key role in People's Daily Lives and make a great contribution to people's quality of life.

Products&Application

Product Specification

Product Name | High Performance Mirror | “V95” | |

Substrate Specification | Material | Aluminium Strip | |

Width [mm] | 1000 … 1250 | ||

Standard Thickness [mm] | 0.3 … 1.0 | ||

Standard Alloy | Depend on Application 1000 series, 5000 series etc. | ||

Temper | H16、H18、H19、H24 etc. | ||

Surface | Pure Al+ Pre-coating | ||

Pre-coat Thickness [μm] | ≥ 4μm | ||

Mechanical Property | Tensile Strength [N/mm²] | 300 ~ 320 | |

Yield Strength [N/mm²] | 270 ~ 300 | ||

Tension Uniformity across strip [%] | ± 2.5 | ||

Tension Uniformity along strip [%] | ± 5.0 | ||

Elongation [%] | ~ 5% | ||

Bending Radius for forming | ≥ 1.5 x strip thickness | ||

Physical Property | Density [g/cm³] | 2.7 | |

Optical Property | Total reflectance (Y / D65 / 2°) [%] | 95±2 | |

Diffuse reflectance (Y / D65 / 2°) [%] | < 1.0 | ||

Specular Reflectance (60° longitudinal) [%] | ≥ 91 | ||

Specular Reflectance (60° transversal) [%] | ≥ 91 | ||

Colour (CIELAB D65 10°) | L*: 98 ± 1 a*: 2 … 2 b*: -1 … 1 | ||

Durability Tests

| Test Item | Approval | |

NSS Salt water spray test (as coated / 72hours / ΔY% < 1%) | ΔY% < 1.5% | ||

Cross hatch adhesion test (no test fields delaminating) | 0 delamination of 100 fields | ||

Oven Test (180°C / 2h / ΔY% < 1%) | ΔY% < 0.5% | ||

Climate Chamber (40°C - 95% r.H. / 168h / ΔY% < 1.0%) | ΔY% ≤ 1.0% | ||

Climate Chamber (85°C - 85% r.H. / 24h / ΔY% < 1.0%) | ΔY% ≤ 1.0% | ||

UV test (continuous test for 2weeks / ΔY% < 1.0%) | ΔY% ≤ 1.0% | ||

Form Tolerances | Thickness Tolerances for coils and sheets [mm] | 8% of gauge | |

Width Tolerances coil [mm] | +2.00/-0.00 | ||

Width Tolerances Slit coil [mm] | +0.06/-0.00 | ||

Longitudinal Curvature coil [mm] | ≤ 1 per 1000mm length | ||

Sheet Sizes [mm] | < 1250 (width) < 4000 (length) | ||

Sheet Size tolerances [mm] | +0.50/-0.00 (< 500mm) +1.50/-0.00 (500 - 2000mm) +2.50/-0.00 (2000 - 4000mm) | ||

Home | About Us | Products | Service | News | Download | Contact Us | Privacy Policy